- Description

UNLIMITED SPACE OF OPPORTUNITIES

The ATMAT Jupiter

printer is the first

commercial, heavy-duty 3D printer to have a work platform with dimensions of

2000 x 1000 x 1000 mm. Creating a machine with a large-format work surface

gives a wide range of printing options for spatial models, while limiting the

production capacity. The device has been designed to improve the production

process of various industries, becoming a competitor for large-size CNC

machines. Systematic use of the printer allows the company to reduce the costs

and production time of specialized tools. The development of a 6-zone heating

system for the granite working table contributes to uniform distribution of heat

on the entire table surface, ensuring perfect adhesion. Bearing in mind all the

HSE requirements in place, we have created an industrial machine that can be

operated in a workshop environment.

WORKING AREA

ATMAT Jupiter printer

was created in order to eliminate the biggest limitation in 3D printing technology,

which is the size of the working field. The work platform with dimensions 2000 x

1000 x 1000 mm is one of the largest currently available on the commercial

market. Its implementation allows the

user to create large-size printouts easily, without the need for further

processing. This allows you to reduce production time and user workload,

resulting in a significant reduction in production costs.

FULFILLED HSE REQUIREMENTS

To

ensure HSE requirements are fully met, at the stage of design all the

strict health and safety requirements have been considered, including a luminous signal indicating stages of the printer's operation, specialized marking on

dangerous elements and appropriate emergency buttons allowing for immediate stoppage of the

machine. It makes the printer a heavy-duty, professional machine, suitable for use in

production workshop environment.

MULTI-PORT PRINTING HEAD AND EXTRUDER SUPPORT

Highly

innovative, high-performance multi-port head system has become a breakthrough

in the large-scale 3D printing. When designing those heads, we tried to supply

them with a quadruple and a single extruder and two nozzles, ultimately

creating 5 extruders. The use

of the 4 + 1 system allowed to achieve excellent results of the device's

working time without compromising on the printout surface quality. The fluidity

of the material flow guarantees

appropriate implementation of the basic 3D printer design assumption - an

uninterrupted work. As a

result, it translates into high efficiency, accelerating and streamlining the

production process.

THERMO-INSULATED, HEATED CHAMBER

Most

filament materials currently available on the market require a heated working

chamber to achieve the best results. Maintaining constant temperature

inside the working chamber

is a fundamental aspect affecting the visual appearance and all material

properties. Equipping the device with thermal insulation means that a constant

temperature is maintained inside the chamber all the time, creating an

appropriate working environment and

the vapours emitted in printing are removed by the forced ventilation system.

GRANITE WORK TABLE WITH 6-ZONE HEATING SYSTEM

When

designing the work platform, an important aspect was to provide a stable structure

that would guarantee adequate adhesion between the table and the model being

printed. The granite table we used has been additionally equipped with a

6-zone heating system, ensuring

quick operational readiness of the device, while reducing the energy consumption

needed to heat such a large work platform. The table structure, which is easy

to disassemble, enables quick cleaning of surfaces surfaces having a

significant impact on the printing process.

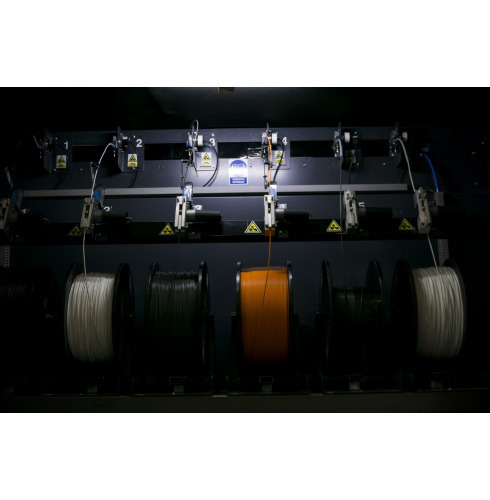

CAPACIOUS FILAMENT CABINET

When

designing a large-size 3D printer, we took care of its uninterrupted work,

which is a fundamental principle to print large format printouts . We have

created a filament cabinet housing 5 specially designed reels with filaments

having total weight of 50 kg. This

solution will guarantee long-lasting printing and constant operation without having to replace reels with material.

FILAMENT NO-FLOW SENSOR

Filament flow is controlled by means of five specially

designed sensors placed in the cabinet of the

device. During operation, the sensors monitor the flow of material uncoiled

from the reel, and, in case of anomalies, inform the user by displaying a

message on the control panel. At the same time, the printing process is stopped

and remembered by the machine. Printing will be continued once the failure or

breakdown is rectified. Thanks to the intelligent sensor systems collecting key

information about the device's operation, the machine can react

immediately.

FILAMENT AMOUNT CONTROL

In the production of large-size prints, the amount of

filament used must be controlled in order to avoid process failure. For this

purpose, a system measuring weight of the filament was created and it measures the amount of remaining

material on the reel located in the cabinet. The system allows for early detection of failures

related to material shortage and diagnose the printer's operating status, making possible the

multi-week printing.

INNOVATIVE SYSTEM OF XY SYSTEM DRIVE

We

equipped our device with an innovative system for driving the XY system with

linear drives. This improvement is unprecedented in 3D printers but allows for

seamless development of high speed and precise positioning resulting from the

lack of play that appears in screw drives, belt drives and transmissions.

CUSTOMISATION IN ALL RESPECTS

Engineering

solutions were selected in such a way as to assure full freedom in terms of

material and print parameters. The ATMAT Jupiter, due to its direct type

extruder, works with a wide range of filaments available on the market - from

typical solutions, such as PLA, PET, ABS, elastic materials to rubber or

plastics with admixtures of wood, metals or mineral additives. The versatility

of the printer in terms of model preparing software for printing is also an indisputable

convenience. We have appropriate profiles for both free and commercial slicers.

POLISH PRODUCTION, SUPPORT AND SERVICE

When it

comes to our products, we always focus on the highest quality, imprinted both

on production, sales and after-sales services. Every single device we make is

manufactured in Poland - all products are designed, tested, produced and stored

in Poland. Our qualified specialists - engineers with extensive experience -

make every effort and do absolutely everything possible to assure products

leaving our factory meet the expectations of even the most demanding customers.

In addition, we provide fast and fully professional after-sales service (during

the warranty period and after). We provide assistance in both the initial

configuration of equipment and advise on its further operation.

SPECIFICATION

DEVICE OPERATION

print technology FFF (FDM)

number of heads 2

number of extruders 5

working area X: 2000 Y: 1000 Z: 1000 mm

layer height 0.2 - 2 mm (depending on nozzle diameter)

filament diameter 2.85 mm

nozzle diameter 0.5 - 5 mm

print speed in HQ

mode 100 mm/s

positioning accuracy

of the X/Y axis 50 μm

filling speed 200 mm/s (depending on nozzle diameter)

positioning accuracy

of the Z axis 10 μm

DEVICE

printer dimensions 4100 x 2300 x 2600 mm, 2600 kg

print materials PLA, PET-G, ABS, TPU, Nylon

support materials PVA,

extruder direct

communication USB

printing environment closed, heated work chamber

working table granite slab

max. table

temperature 100°C

heated chamber yes (option)

max. chamber temperature

50°C

max. head temperature

350°C

TECHNICAL

SPECIFICATION

power 400 V

software package Simplify

supported

formats .gcode