- Description

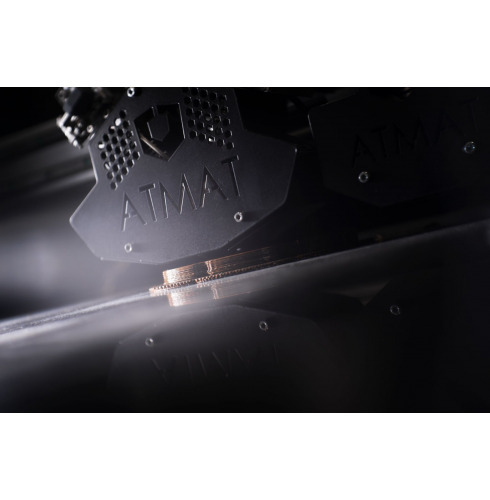

THE NEW FACE OF PRODUCTION

The ATMAT Saturn printer is an innovative device created for the

production of large-size models using incremental technology. The robust and

stable construction is accompanied by heavy-duty, industrial components. The

implementation of state-of-the-art engineering solutions makes the device a

precursor in the field of large-size 3D printing using FFF technology (Fused

Filament Fabrication). The granite table with a working area of 1200 x 1000 x

1000 mm has excellent adhesive properties and has additionally been equipped

with a heat-insulated heating chamber to make even very demanding printouts

possible. The device is equipped with a high-performance double head, extruder

support system and filament no-flow sensor.

Operation

of the device is controlled by our original software, which was created

specifically for our printer line-up. The machine has been designed in such a

way that all the occupational HSE requirements imposed by applicable directives

are met. All these possibilities, enclosed in the metal casing, make ATMAT Saturn a professional, heavy-duty machine producing

printouts of the highest quality.

WORKING AREA

The

large-format workspace offered by the ATMAT Saturn printer is a unique feature as comparedto other

devices utilising this technology. It allows you to create large format

printouts,

without compromising on

quality. Designing a printer with a working area of 1200 x 1000 x 1000 mm,

we aimed to create a machine

competitive for large-size CNC machines, reducing the costs and production time of specialized tools.

FULFILLED HSE REQUIREMENTS

The

dimensions of the device, its advancement and operation in workshop environment

require strict

compliance with applicable health and safety rules. The ATMAT Saturn printer has been equipped with health and safety

arrangements such as an emergency button or a lockable device design, which

makes the machine safe for operatives and the environment.

HIGHLY EFFICIENT DOUBLE HEAD AND EXTRUDER SUPPORT

Implementation

of high-performance double head with support allowed us to fulfil the key function

of the printer, which is continuous work and high quality of printouts

produced. In designing the heads we

tried to supply them with a double and a single extruder and two nozzles,

creating eventually 3 extruders with a 2 + 1 arrangement. The head has been

designed in such a way as to guarantee the correct feed of the filament when

working with small series printouts, as well as high-volume production. In

addition, equipping the printer with the height adjustment of the auxiliary

head significantly

reduces the occurrence of problems

with printing using two heads at the same time.

AUTOCALIBRATION OF THE WORKING PLATFORM

Autocalibration

of the working table in the device makes the printer an intuitive machine,

properly equipped with all necessary arrangements to ensure trouble-free

cooperation with the user. Using the autocalibration function, we have eliminated

the risk of incorrect settings of

the working table once and for all, thus ensuring the correct start of the

critical, first layers of the printout.

THERMO-INSULATED, HEATED CHAMBER

Maintaining a constant temperature in the working chamber

of the printer is a fundamental

aspect affecting proper operation of the device. Designing a large-size

industrial machine provided the basis for arranging a closed, thermo-insulated

and heated working chamber, necessary for printing out of demanding materials

used in production of industrial quality components.

GRANITE WORK TABLE WITH 4-ZONE HEATING SYSTEM

A heated work platform is now a requirement for printouts made of wide range

of available filaments. The table has been equipped with a 4-zone

heating system to reduce energy consumption

necessary to heat its large volume body and ensure quick operational readiness.

Implementing the granite slab as a working platform was prompted mainly by a

very good adhesive properties, so preparation of work is not a problem anymore.

INTELLIGENT

SYSTEMS FOR CHECKING THE MACHINE OPERATION

The

printer has been equipped with an intelligent control systems allowing the user to quickly respond to emerging

situations. The device has been equipped with, among others, filament no-flow sensor, designed to prevent sudden interruption of printing,

and a filament

weight sensor to monitor the quantity of material needed to print

the prepared model. High reliability

of those intelligent device control systems translates into process stability

and excellent print surface quality. What is more,implementation of a

compressed air cooling system enabled more efficient cooling using the air from

outside the machine.

MACHINE ERGONOMICS

When

designing the device, we incorporated a number of innovative improvements to

facilitate operation of the printer. Integration of control panel with the

casing, central door hiding in the printer or installation of all cabinets

(including a spacious tool cabinet) on one side of the machine, all the above

accelerate operation of the machine with no quality compromise.

CUSTOMISATION IN ALL RESPECTS

Engineering

solutions were selected in such a way as to assure full freedom in terms

of material and print parameters. The

ATMAT

Saturn, due to its direct type

extruder, works with a wide

range of filaments available on the market - from typical solutions, such as

PLA, PET,

ABS, elastic materials to

rubber or plastics with admixtures of wood, metals or mineral additives. The versatility of the printer in terms of model

preparing software for printing is

also an

indisputable convenience. We

have appropriate profiles for both free and commercial slicers.

POLISH PRODUCTION, SUPPORT AND SERVICE

When it comes

to our products, we always focus on the highest quality, imprinted both on production,

sales and after-sales services. Every single device we make is manufactured in Poland

- all products are designed, tested, produced and stored in Poland. Our qualified

specialists - engineers with extensive experience - make every effort and do

absolutely everything possible to assure products leaving our factory meet the

expectations of even the most demanding customers. In addition, we provide fast

and fully professional after-sales service (during the warranty period and

after). We provide assistance in both the initial configuration of equipment

and advise on its further operation.

SPECIFICATION

DEVICE OPERATION

print technology FFF (FDM)

number of heads 2

number of extruders 3

working area X: 1200 Y: 1000 Z: 1000 mm

layer height 0.2 - 1.5 mm (depending on nozzle diameter)

filament diameter 2.85 mm

nozzle diameter 0.5 - 3 mm

print speed in HQ

mode 100 mm/s

positioning accuracy

of the X/Y axis 50 μm

filling speed 200 mm/s (depending on nozzle diameter)

positioning accuracy

of the Z axis 10 μm

DEVICE

printer dimensions 2600 x 2000 x 2300 mm, 1500 kg

print materials PLA, PET-G, ABS, TPU, Nylon

support materials PVA

extruder direct

communication USB

printing environment closed, heated work chamber

working table granite slab

max. table

temperature 100°C

heated chamber yes (option)

max. chamber

temperature 50°C

max. head temperature

350°C

TECHNICAL

SPECIFICATION

power 400 V

max. power

consumption 9000 W

average power

consumption

in operation (for

PLA) 1500 W

software package Simplify

supported

formats .gcode